Full Cat Running

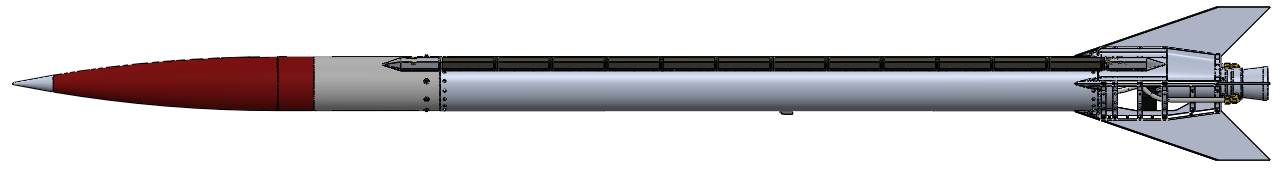

Full Cat is a 6-inch diameter liquid bipropellant rocket powered by a 750-lbf nitrous oxide / ethanol motor, with a projected maximum burn duration of 15 seconds. Its objective is to reach an apogee above 50,000 feet (AGL). RASAero simulations project that this rocket may reach speeds of up to Mach 3. The thrust number is still tentative and may be changed.

Full Cat is constructed primarily from aluminum, with most of the body being propellant tank. Below the tank is an rib-cage structure which keeps the fins stiff and prevents buckling or twisting; the fins themselves are also aluminum, and transfer force from the thrust chamber into the tank. Above the tank is a composite airframe made of fiberglass for strength and radio transparency; most of the volume is taken up by the recovery system, with electronics nested in the forward tank bulkhead.

Below you will find the HalfCatSim data for Full Cat, generated in v1.2.1. Note that at the time of writing the system has not been fired, and is awaiting thrust and pressure data collection to anchor the simulation.

Some notable similarities and departures from other vehicles can be seen in these CAD screenshots. The fuel is stored in a stacked-tank above the oxidizer with a sliding piston to push it out the top and into an external downcomer, as is the case with 2Cat/3 and 1Cat/4. (Not pictured in the cutaway is a hard stop which the piston initially sits on) However, unlike all of our other engine systems to date, both main propellant valves are integrated to their respective bulkheads. This greatly simplifies the plumbing system, reducing the number of fittings and freeing up space in what is historically the most volume-constrained section of the rocket directly between the tank and thrust chamber.

Rather than join two separate tanks and place the nitrous vent between, as in 2Cat3, or drill a static hole directly through the wall, as in 1Cat/4, Full Cat utilizes a dip tube which pulls air and nitrous gas out from the top of the oxidizer tank, directly below the piston, and routes it down to the bottom where it can pass through an automated vent valve prior to exhausting overboard. As in 2Cat/3, the automated vent valve shuts the static nitrous vent once the main oxidizer valve has opened to mitigate venting losses during burn.

Full Cat’s motor is regeneratively cooled by the fuel. The mixture ratio is kept very low at roughly 2.2:1 to lower the combustion temperature and increase coolant flow rate. The fuel itself is E98 (98% ethanol, 2% gasoline) with a small amount of silicone oil mixed in; this is based on research papers which show a reduction in heat flux through the wall by the application of a self-renewing SiO2 thermal barrier coating.