Automated Vent Valve

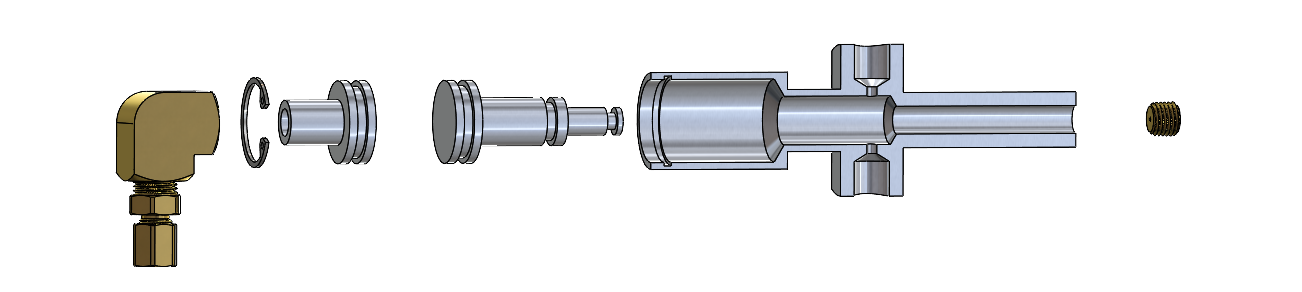

During filling of the oxidizer tank, nitrous oxide vapor will be allowed to escape through a static vent port, just like in almost all amateur hybrids as well as the Half Cat engine. But rather than a simple fitting with a small hole, the static vent is part of a fluid pressure-actuated valve, which is connected to part of the main oxidizer valve. While the tank is being filled, the pressure of the escaping nitrous vapor will be holding the vent valve piston in the open position; at this time, there is no force trying to close the valve. When the main oxidizer valve is opened, however, pressure will enter the inlet on the side of the vent valve where it acts on the larger diameter end of the piston. Because pressure from the main oxidizer valve is acting on a larger area than the pressure from the escaping nitrous vapor, the piston will be pushed into its closed position, even though the pressure on both sides is the same. When the engine is done firing and the spring return closes the main oxidizer valve, there will no longer be any pressure acting on the large end of the piston. The pressure on the small end will push it back into the open position, venting the remaining pressure in the oxidizer tank.

Open State:

Closed State:

Because the pressure in the tank is what opens the vent valve, there is no risk of pressure being trapped inside the tank. Even if the valve were to become stuck due to contaminant particles or icing, it would be forced open by the pressure of the warming nitrous vapor well before the tank was in any danger of bursting. If for any reason the vent valve could not be reopened, the tank would not exceed 80 PSI, as the main valves would reopen against the return spring above that pressure. The vent valve is effectively the equivalent of a normally-open solenoid, just with a different means of actuation.