1Cat/4

THRUST: 50 - 80 lbf

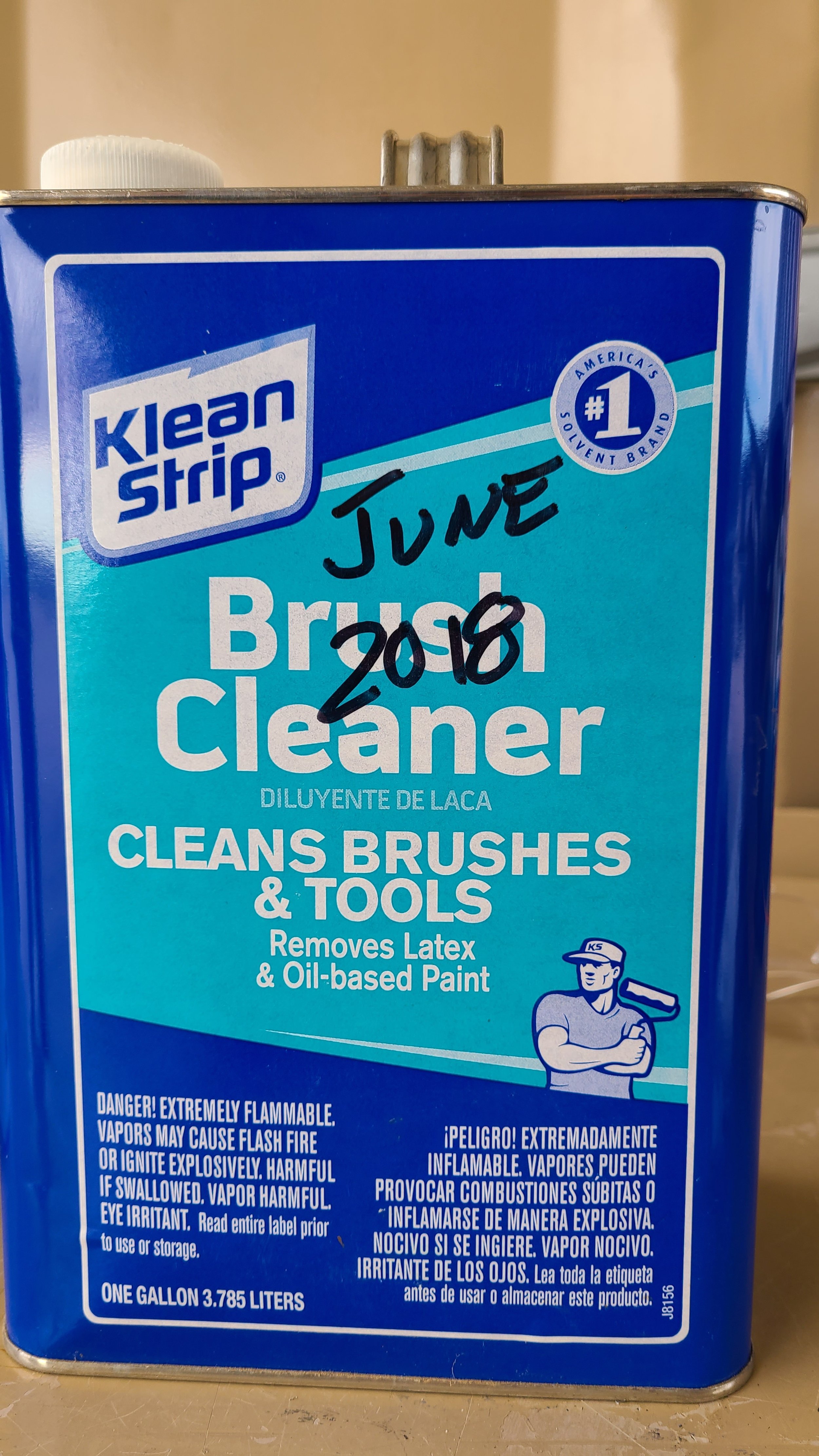

FUEL: isopropanol, acetone, Brush Cleaner, Kerosene

OXIDIZER: NITROUS OXIDE

bURN TIME: 3 ± 2 SECONDS

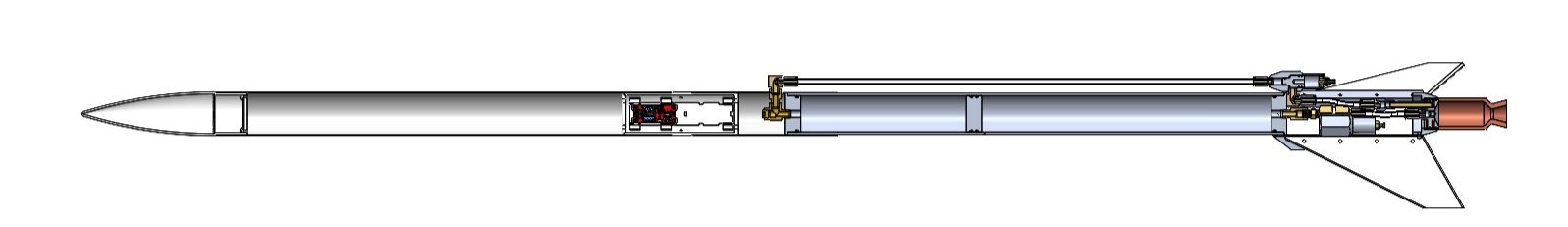

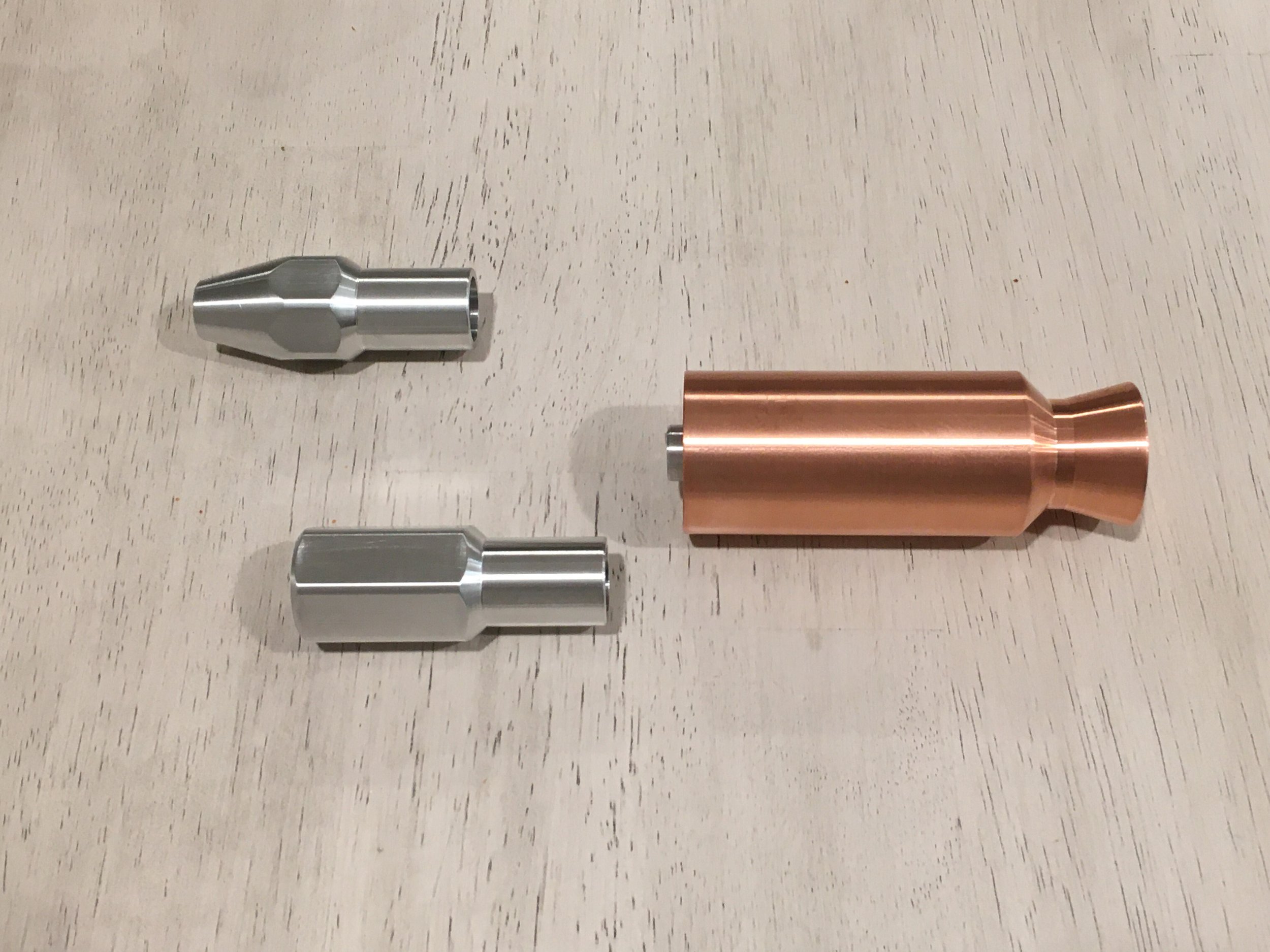

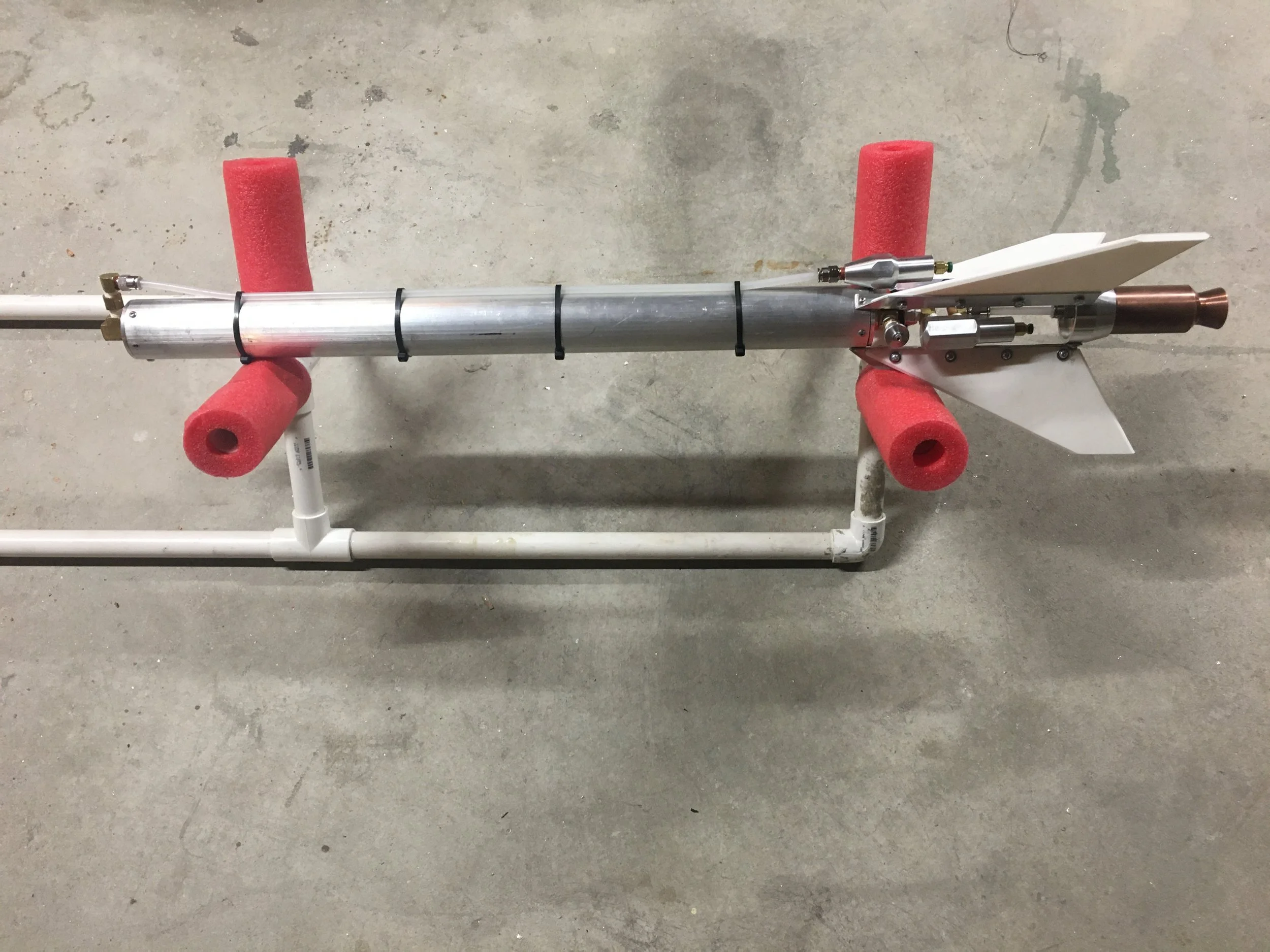

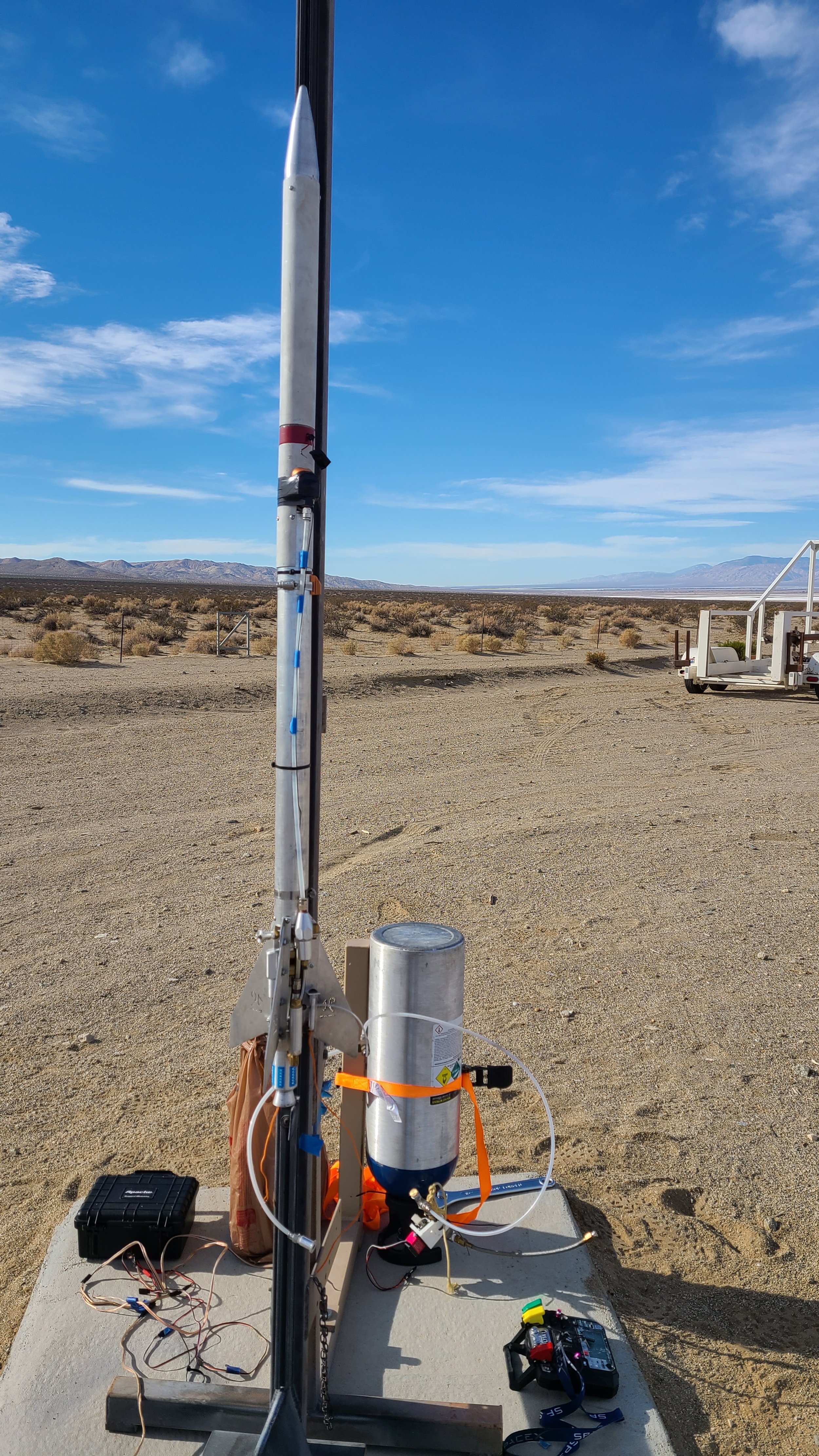

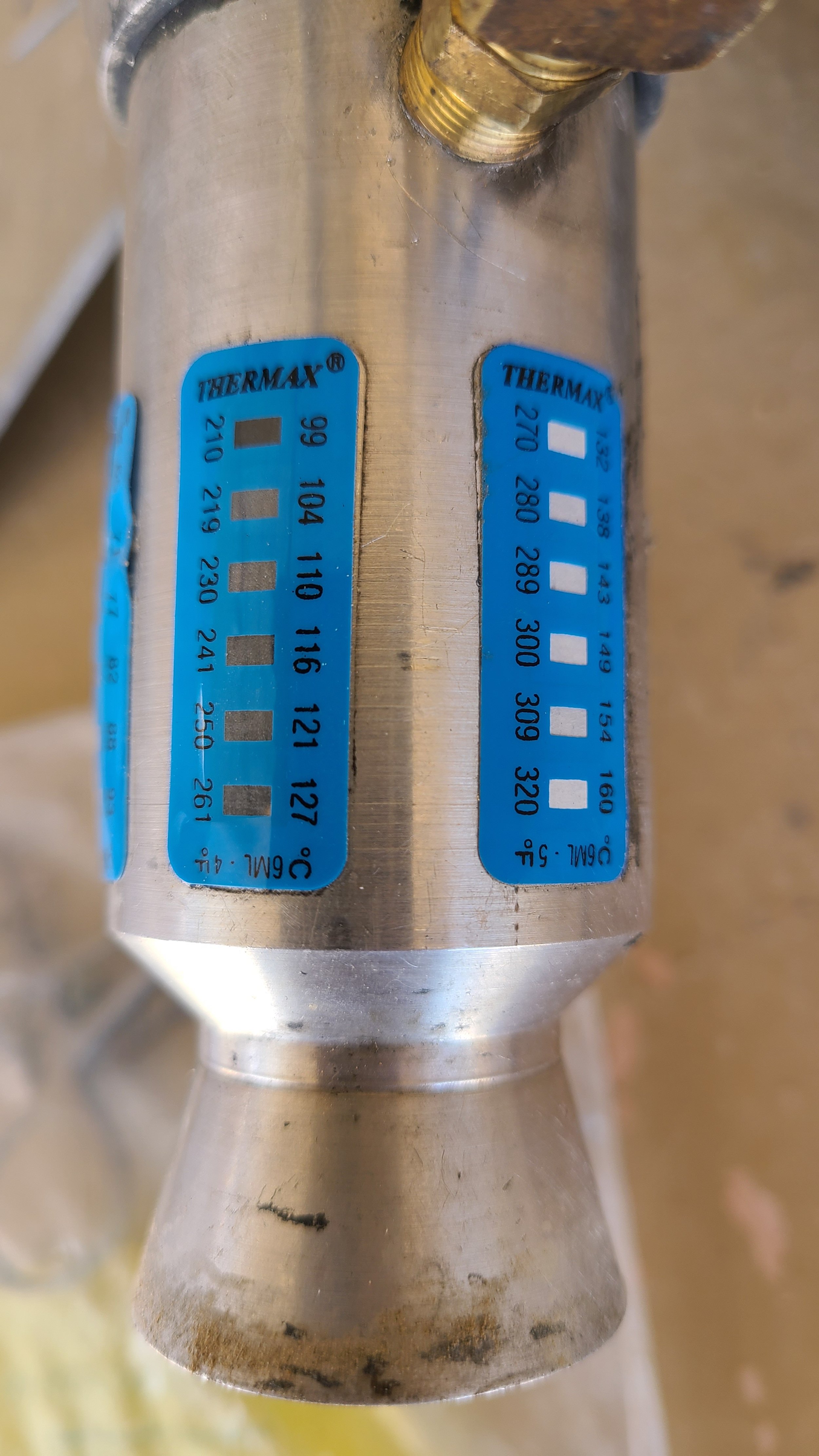

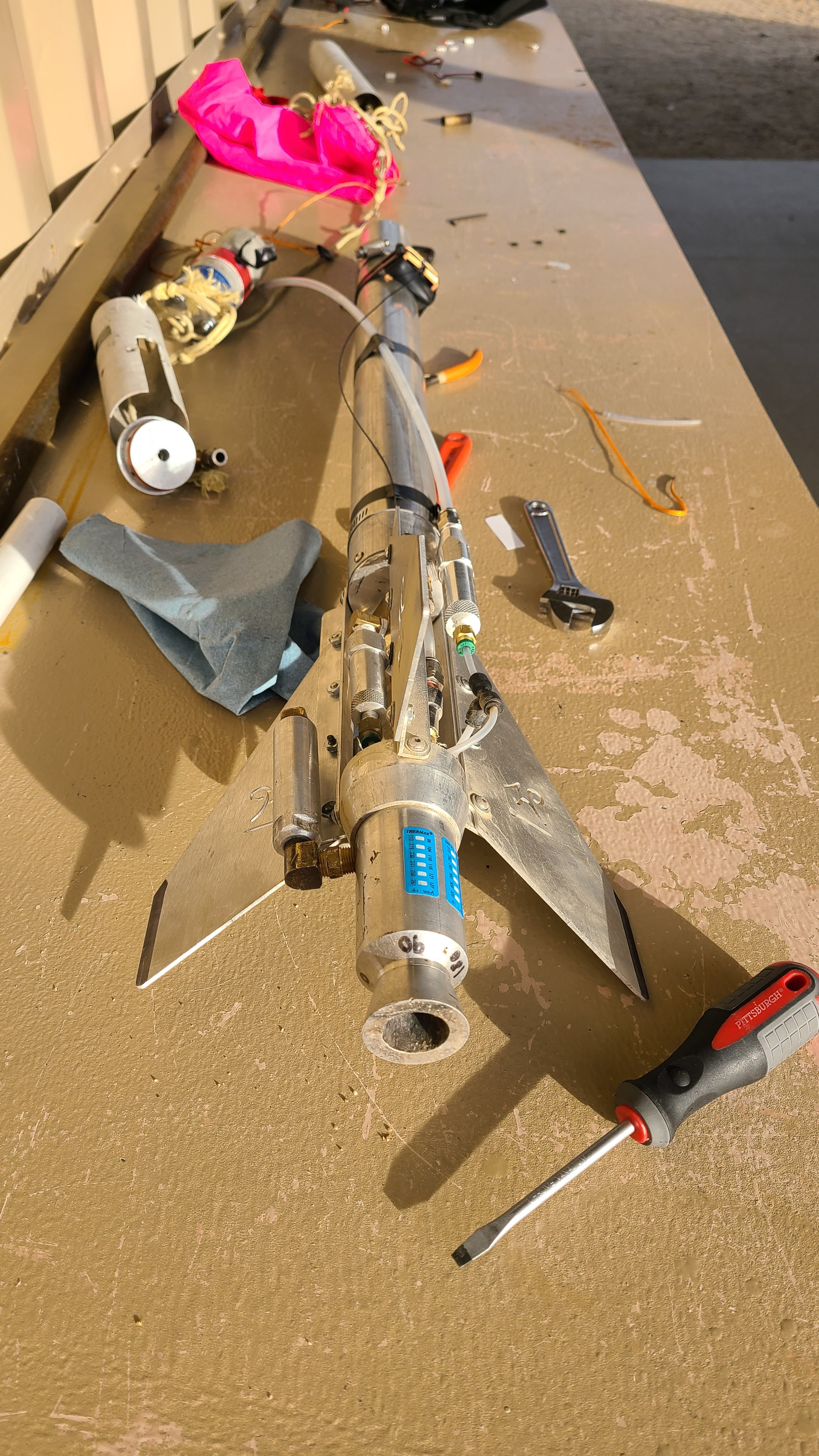

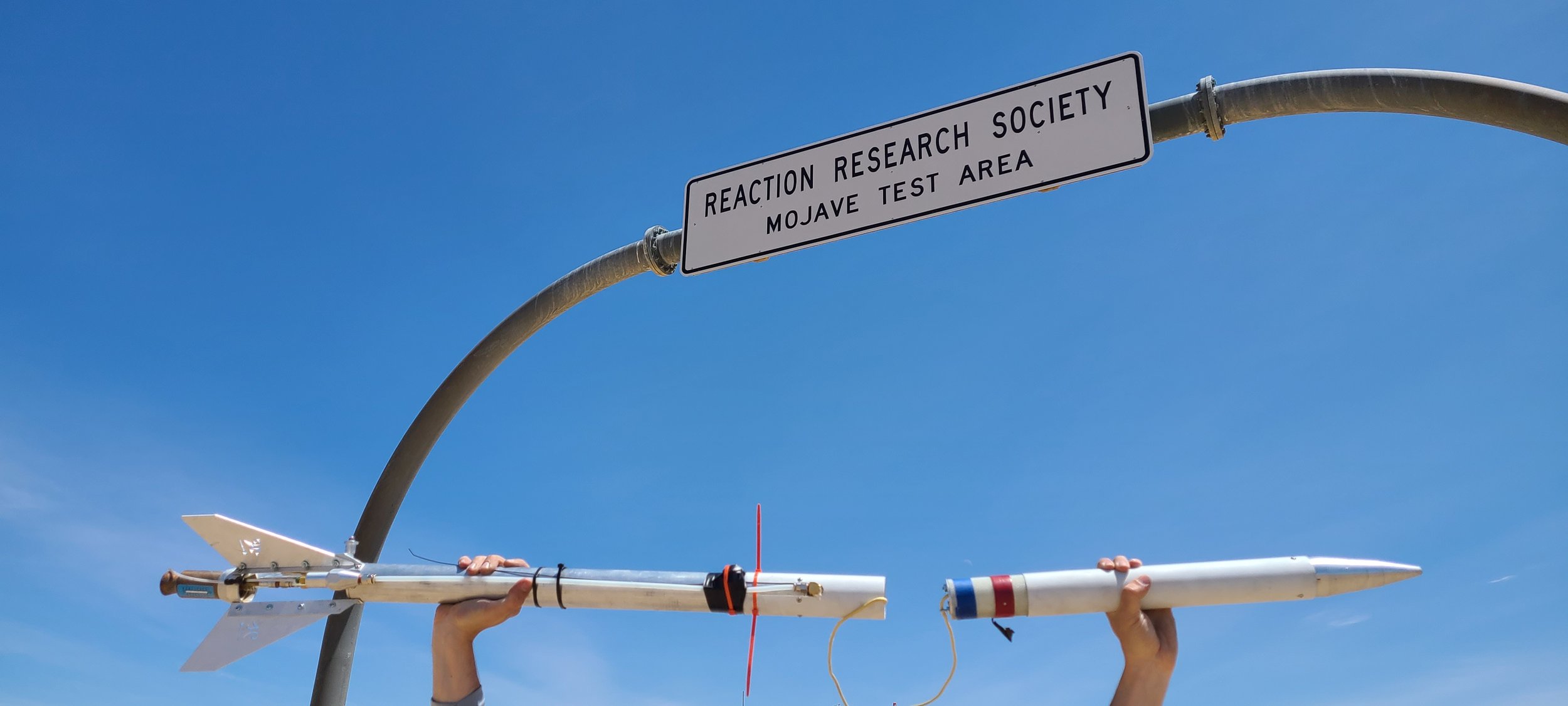

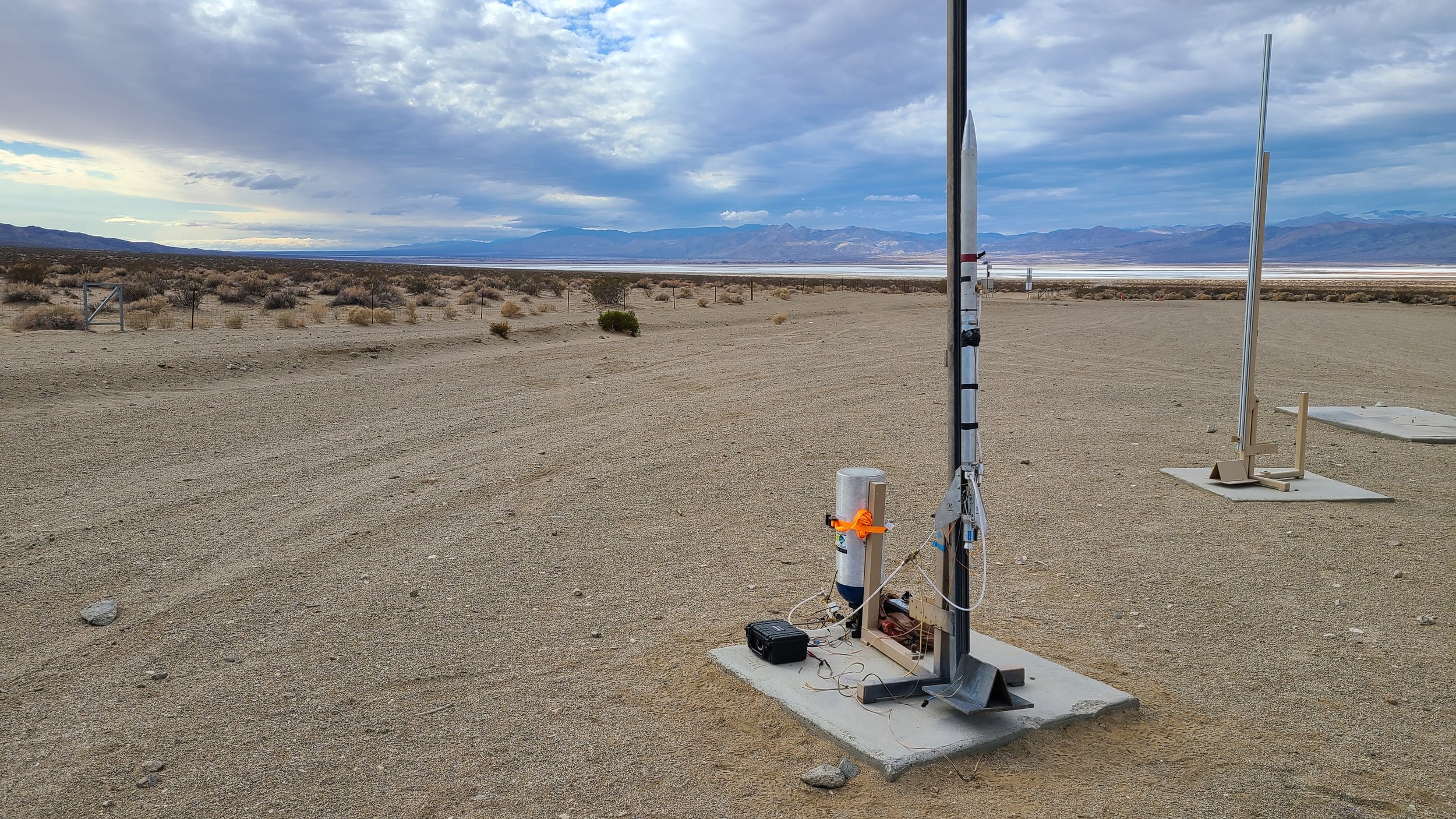

1Cat/4 was a very simple simple liquid motor built to test out a number of new technologies. In its intial configuration, it had a heatsink combustion chamber retained onto the impinging-doublet injector with a snap ring, and two pneumatic Half Cat valves which triggered by a pyrodex pellet melting open the pilot line. The pyrodex pellet was located inside the chamber and also served as the igniter.

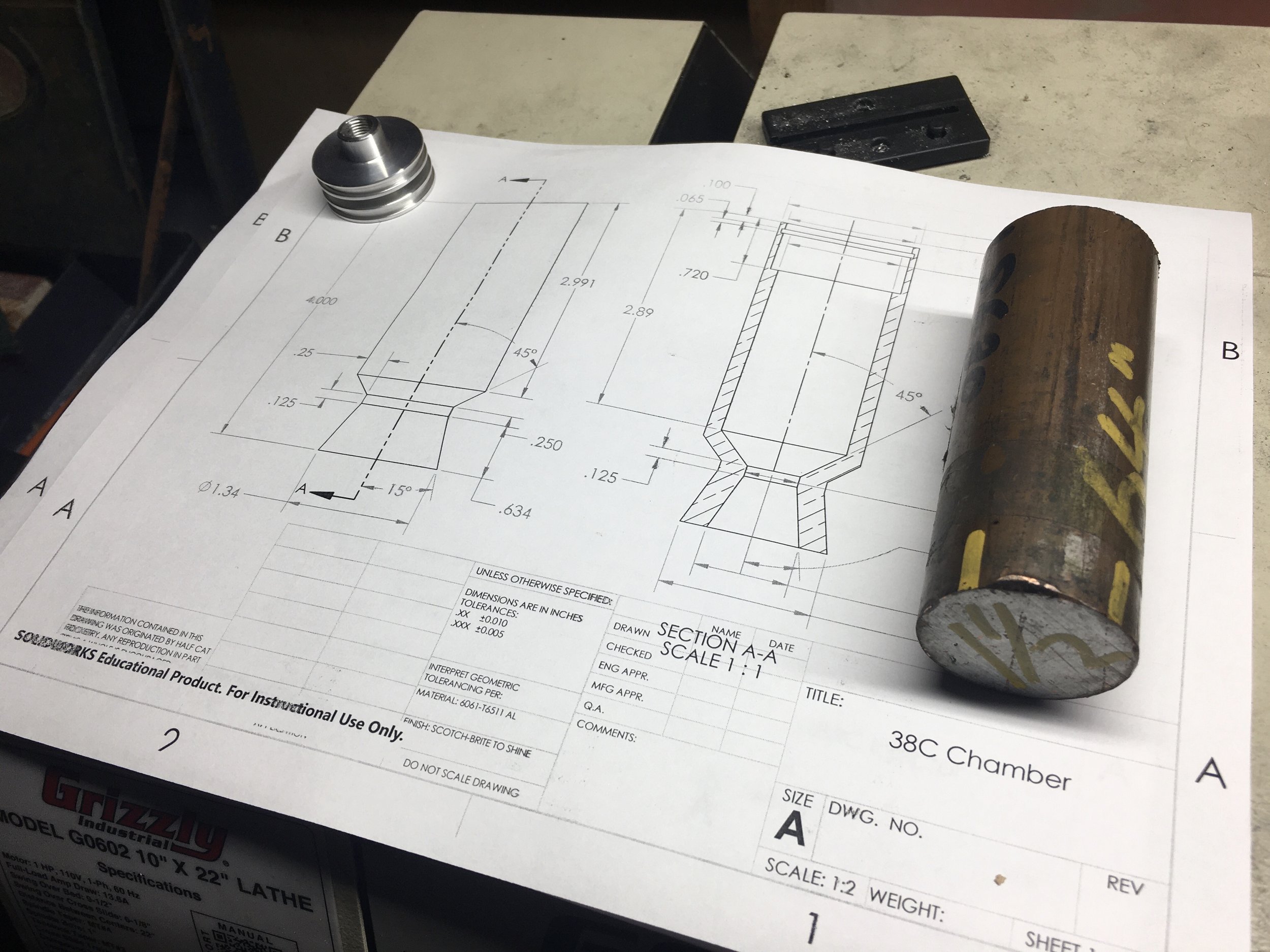

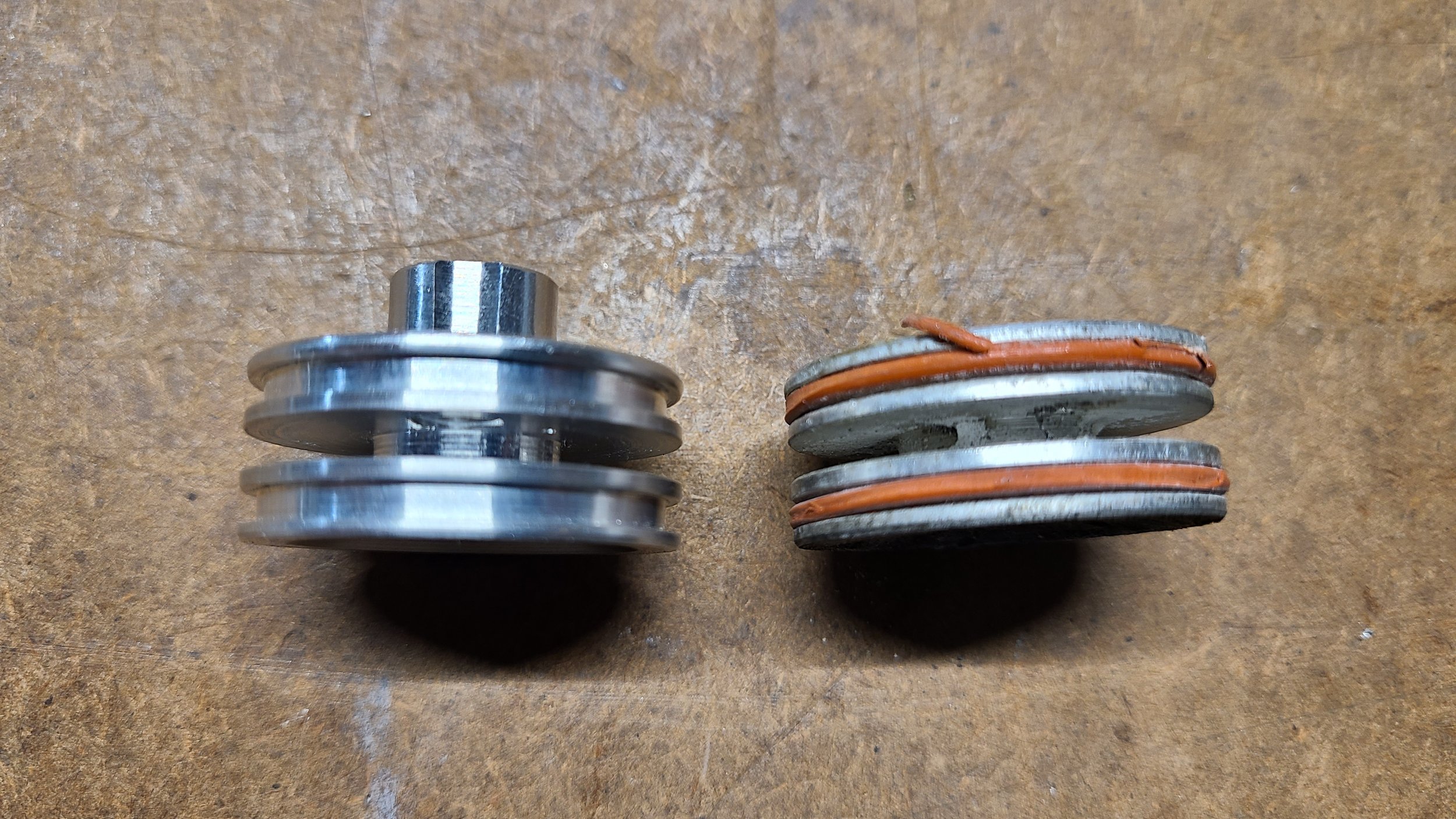

A heatsink combustion chamber is one which is made of a large, relatively high-mass piece of metal with good thermal conductivity. Rather than regenerative or ablative cooling protecting the chamber from heat, the metal absorbs it and increases in temperature. Heatsinks are best used with short burn times and low flame temperatures. While not usable for as long a time nor is as extreme conditions as regenerative or ablative systems, this type of chamber is extremely simple to produce.

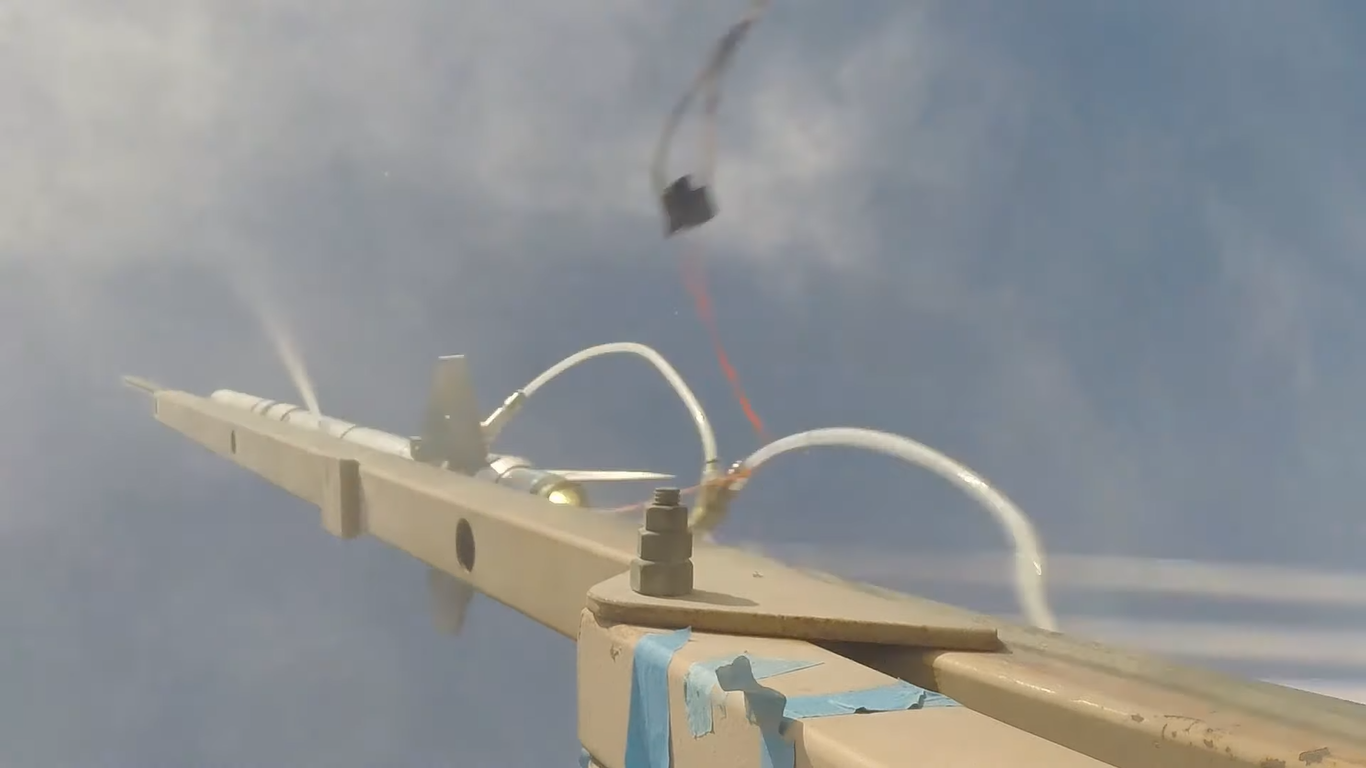

In its later flights, the igniter was changed to a cartridge-style system, where a small Estes blackpowder motor with the nozzle removed was lit with an e-match, providing reliable ignition of the main chamber. Later flights also saw the introduction of the “Tabby” regeneratively cooled thrust chamber, though with limited success on 1Cat/4.

1Cat/4 was perhaps the most important development rocket in the history of HCR, proving out a number of consequential features that would make their way into later vehicles.

Tests & Launches

Launches 1-8: Heatsink Chamber

Launches 9-10: Regen Chamber

No static test has been conducted on 1Cat/4, since its purpose is to demonstrate rapid and repeatable bipropellant flights as well as flexibility in propellant combinations. The vehicle has undergone numerous repairs, reconfigurations, and hardware changes to experiment with new designs and technologies.