Half Cat Walking

THRUST: 120 lbf

FUEL: ISOPROPANOL

OXIDIZER: NITROUS OXIDE

bURN TIME: 5 SECONDs

Impulse: 2355 N•S

Click here to read the full history of Half Cat

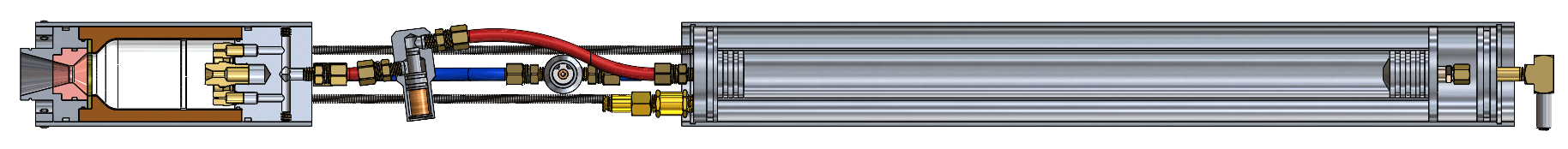

Prior to being named Half Cat, this motor was known as RY-101, an old design number designation. It has conducted seven static fires and three flights and is now retired. Propellant flow is controlled by two independent and identical pyrotechnic valves. It contains a solid propellant igniter which is lit just before initiation of the valves. The oxidizer tank is passively vented through a 0.8mm orifice plug. The combustion chamber is protected by an ablative thermal liner made of CHAMBERSAFE.

Tests & Launches

-

Partial Success (propellant tank exploded post-firing)

No numerical data acquired

Changes from previous test: N/A (well, a lot if you consider the many, many previous iterations of the engine)

Many attempts were made before finally achieving a hot fire (most prior problems involving the electronics in the GSE, after the leaks had been solved), but eventually Half Cat came to life just days prior to our graduation, making this the first liquid bipropellant engine from students at UCF. The burn itself was nominal, but in the minutes following shutdown residual gaseous nitrous oxide continued leaking into the combustion chamber where it kept the remains of the thermal liner on fire until this caused a N2O decomposition event originating at the bottom center of the tanks. The detonation destroyed both tanks and the lower tank bulkhead as well as causing the piston to vanish at speed (we assume it was shot off into the grass, but it is also possible that it was broken into many small pieces and scattered).

Following this test, a new fuel tank, piston, and lower tank bulkhead were fabricated along with a “new” oxidizer tank, which was in fact the originally intended tank before it was switched out for the identical tank belonging to the cold gas CO2 thruster. The lingering fire of the thermal liner spurred the creation of CHAMBERSAFE to eliminate that particular decomposition risk.

-

Failure (combustion chamber exploded during firing)

Partial data acquired

Changes from previous test: Conical interface between piston and lower tank bulkhead to eliminate residual fuel volume, CHAMBERSAFE thermal liner

Unfortunately, due to a recycled firing attempt, our good cameras died and the above is the best video available. On this occasion, one filling cycle had already been attempted but was aborted just before ignition due to the oxidizer fill tube disconnecting at the end of the fill. As a result, the supply tank was now only half-full and significantly colder - and therefore lower pressure. When filled a second time and ignited, the lower tank pressure meant that the combustion chamber pressure could become greater at a certain point on the injector and reverse flow through one or more orifices, forcing hot gas into the oxidizer manifold and causing nitrous oxide to again decompose explosively.

Following this test, a new combustion chamber and injector were fabricated along with a “new” nozzle to replace the graphite ones which had both been broken in tests 1 and 2. The nozzle was made for the original iteration of the engine, but since it was the only one left on hand it became the replacement for test 3. The CHAMBERSAFE liner was not properly tested this time, as it shattered when the injector detonated.

The results of test 1 and 2 - that a decomposition event and explosion could occur on both sides of the plumbing without propagating to the other side - led to the realization that the nylon tubing of the propellant feed lines act as burst discs; it pops quite easily under unexpected stress.

-

Success

No numerical data acquired

Changes from previous test: New fitting-based injector, copper nozzle, replacement of bolted retainer tail-cone with regular bolted retainer due to concerns of gross overexpansion

Had the data acquisition system been working, this test fire would have qualified the engine for flight. The lingering fire appeared again in this test, however it eventually snuffed itself out. This is believed to be the CHAMBERSAFE, which is normally self-extinguishing in atmosphere thanks to the release of H2O and CO2, being fed by residual nitrous oxide. A reflection inside the camera lens provided a good view of the Mach diamonds retreating as the combustion pressure decayed.

-

Partial success (test stand fell over)

Partial data acquired

Changes from previous test: None with the engine

Test 4 was necessitated by the lack of data in test 3, attributed to a bad microSD card. This time a CO2 purge was added to the vent assembly to extinguish the chamber following shutdown, and it did perform as expected. However, what was not expected was the test stand suddenly reconfiguring itself into a horizontal position despite its rigidity in prior tests. This led to a very odd burn that invalidated the data past the first couple seconds.

The data itself does have some interesting points. At the exact moment where the fluid level in the nitrous tank is expected to dip below and expose the oxidizer inlet to only gas (due to the tank no longer being upright under gravity), there is an immediate decline in chamber pressure and thrust. Also, immediately afterward, the tank pressure spikes when the stand hits the ground and the liquid nitrous sloshes into the pressure transducer at the top.

Due to the anomalous circumstances, the fuel was expended before oxidizer (since the piston will continue pushing the fuel out regardless of orientation). For a brief time, the engine operated in oxidizer-only, nitrous-decomp mode. The three brass fuel fittings on the bottom side of the injector (relative to the Earth, as the engine was now laying sideways) partially melted from the lack of fuel flow actively cooling them.

-

Success

Full data acquired

Changes from previous test: None with the engine (Substantially more weight added to test stand legs)

The final static test prior to the first launch was successful in all regards, especially photography, which provided excellent imagery of the Mach diamonds at various stages of operation. For whatever reason, Half Cat has several distinct phases which includes the extremely fiery portion that appears in every test and temporarily obscures the Mach diamonds in this video. Counterintuitively, this fiery phase corresponds to the period of highest thrust. The exact mechanisms behind the thrust curve are not well understood (notably, what causes the distinct plateaus in thrust).

-

Success

No data acquired

Changes from previous test: Fuel line switched out for high-pressure nylon

This was the first firing of Half Cat after Launch 1. It is also the only one performed in daytime, owing to how quickly we were able to set up the test after going through the procedure dozens of times before. Once again, the DAQ output was corrupted on the microSD card, but by visual and audible observation the engine appeared to perform nominally.

-

Success

Full data acquired

Changes from previous test: Oxidizer line replaced with high-pressure version

With both propellant lines switched to the high-pressure version (since the low-pressure oxidizer line was still bursting in separate tests following static test 6), we performed a final test to qualify the engine for flight. Everything went smoothly and we got good data from the DAQ. The spike in thrust and chamber pressure for the first second is attributed to the igniter still burning and generating pressure, which can also be seen in the noticeably bigger initial plume.

-

Partial Success

Mid-air explosion

The first launch of Half Cat took place on April 3rd, 2021 after an extremely intense week of constructing an airframe day and night while preparing everything needed for the trip. On the rocket’s first attempt at filling oxidizer Saturday morning, the fuel line burst due to higher pressure than had been experienced in prior static tests.

Nitrous oxide saturation pressure is dependent on temperature. In this case, the Mojave desert in the daytime was appreciably hotter than the Florida nighttime conditions we had been testing in. The nylon plumbing lines were being used above their rating - this is the case for many fittings and parts on the rocket, but we accept that as a risk. Unfortunately for this first flight attempt, the elevated temperatures bumped the oxidizer pressure just enough above the material’s failure point, so that the fuel line (which is also pressurized by the nitrous oxide) burst approximately 10 seconds into the oxidizer fill cycle.

After the nitrous tank emptied itself (through the always-open static vent), the rocket was disassembled, re-fueled, and reassembled for a second attempt in an impressively short time frame. Knowing the result was likely to be the same, we chose to proceed with a launch regardless of how what was going to happen.

When the fuel line again burst shortly into oxidizer fill, the igniter and valves were initiated. For a second, the rocket took off and accelerated, running as an almost pure nitrous oxide decomposition thruster since most of the fuel had leaked out. Residual fuel inside the plumbing section, along with nitrous vapor from the disconnected oxidizer fill line, was ignited by combustion gases leaking out of the burst line. The resulting explosion separated the combustion chamber (which landed near the launchpad), while the rest of the vehicle partially deployed its parachutes before hitting the ground.

Despite the explosion, the motor was mostly fine. One valve was freed from the rocket and lost, and the brass fuel injection fittings needed to be replaced, but after replacing these Half Cat was reassembled for static test 6.

-

The second launch of Half Cat took place on the morning of August 21st, 2021. This was the first of two flights that day. We were far more prepared this time and had assembled, fueled, and packed the rocket the night before. The launch proceeded smoothly, with the only anomaly occurring when the quick disconnect failed to disconnect. Since the whole fill line and servo/valve were still connected and swinging off of the rocket, the vehicle spun and coned its way up, significantly reducing altitude. Nonetheless, this was a total success for Half Cat.

Altitude: 3400 ft.

-

After recovering Half Cat Walking, we taped over the cracked body tube (a result of the vehicle landing awkwardly), reloaded the motor, and launched a second time. Everything was identical to the previous flight, including the quick disconnect anomaly. Below is a video from Derek Honkawa which has more views of both launches.

Altitude: 3400 ft.

Below is the HalfCatSim data for this motor, generated in a much earlier and outdated version.